Our vision of enriching human safety comes with great responsibility: To deliver the highest quality of hand protection products to our users working in hazardous environments. We understand that users must feel safe and protected at the same time, trust the Hanvo brand.

The purpose-built in-house laboratory is certified by CNAS, and is accredited by SATRA, an independent body in the UK that is notified by the European Commission for a number of directives and regulations related to personal protective equipment (PPE). The accreditation involves rigorous audits on our internal laboratory including and not limited to:

Obtaining the SATRA accreditation demonstrates that the Hanvo laboratory is performing to the highest standard, supplying compliant products which are relevant to the current safety standards. It also ensures that our users can be confident that reliable testing is carried out on their Hanvo hand protection products.

All Hanvo’s products are subject to stringent testing and quality control measures. Our in-house lab is fitted with the equipment necessary to conduct multiple tests on our gloves relevant to the current safety standards.

An overview below outlines the tests that Hanvo hand protection products are subjected to, the equipment used to test, the test methods utilized, and the safety standards that they comply with.

Equipment: Maxi-artindale Abrasion and Pilling Tester

Test Methods: Take the palm position of the glove as a sample, grind it on standard sandpaper. Count the number of revolutions when the glove is worn out.

Standard: EN 388:2016+A1:2018

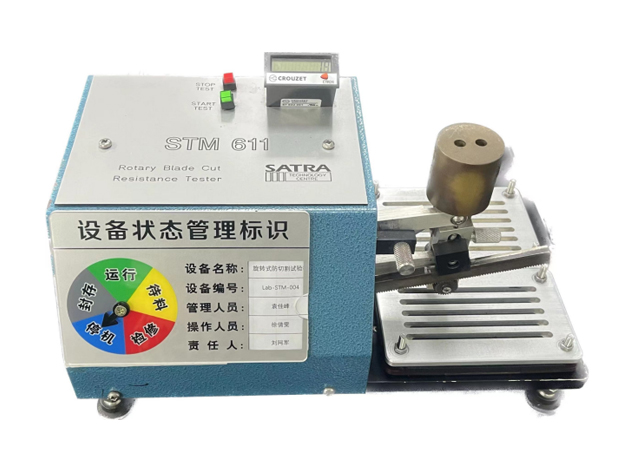

Equipment: Blade Cut Resistance Tester

Test Methods: The test sample is placed on the machine. The blade is lowered slightly and touches the sample. The counter is set to zero. When the rotating blade penetrates the test sample, the machine will automatically stop. The number of cycles displayed on the workbench screen can be used to calculate the cutting index, which is used to measure the blade cut resistance of the material.

Standard: EN 388:2016+A1:2018

Equipment: SATRA Tensile Tester

Test Methods: Take the palm position of the glove as a sample,tear it apart by pulling force, calculate the required force value and judge the level of tear resistance of the product.There are 4 levels of EN388.

Standard: EN 388:2016+A1:2018

Equipment: TDM Tomodynamometer Cut Resistance Tester

Test Methods: The sample was cut by the blade under pressure in the palm of the glove, and the distance required for the blade to cut through the sample at different forces was tested.

Standard: ISO 13997 (EN388:2016) ASTM F2992-15 (ANSI/ISEA 105-2016)

Equipment: Agilent gas chromatography mass spectrometry analyzer

Test Methods: Take the palm position of the glove (including the middle finger), cut it into pieces of 10mm*10mm size, add the corresponding measured extraction solution, and shock it with ultrasonic wave for 30 minutes to test the content of DMF in the solution. The eu standard requires <1000ppm.

Standard: EN16778:2016

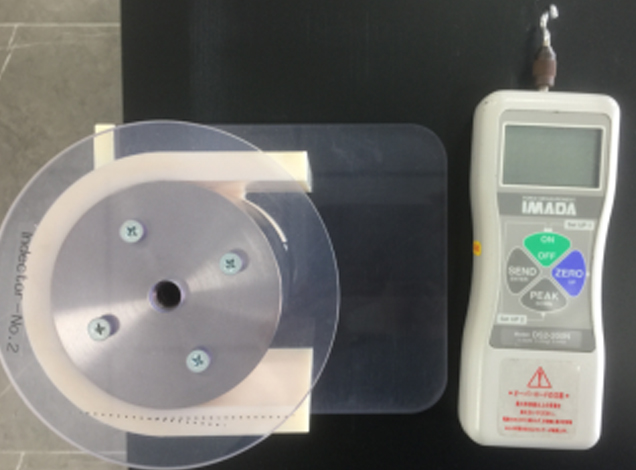

Equipment: Skid proofer tester

Test Methods: Use a fixed gram weight to press the middle finger of the glove and test how much force to pull the glove to determine the anti-skid performance of the product.

Standard: Midori Anzen standard Internally controlled standard

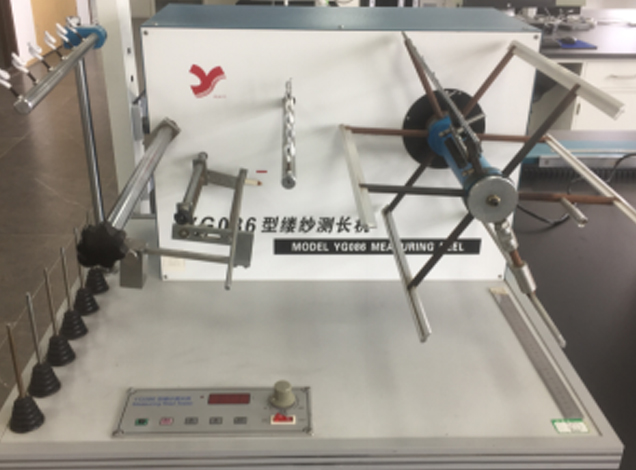

Equipment: Yarn wrap reel

Test Methods: Monitor yarn weight under 100m length to ensure yarn performance meets requirements.

Standard: Internally controlled standard

Rest assured; these are not the only tests conducted to ensure Hanvo’s superior performance. Aside from tests conducted on our hand protection products, our internal lab also conducts various tests on the raw materials used to produce our gloves. Once again, they include but are not limited to these tests below:

Monitors yarn weight to ensure yarn performance meets internal requirements

Monitors the twist of the yarn to measure the strength of the yarn

Determines yarn’s performance by holding a fixed length of yarn to a certain distance and testing how much force it takes to break the yarn.

Our users rely on the exceptional quality of our hand protection products to keep them safe in a hazardous environment which is why, we strive to ensure every pair of gloves receives full quality inspection that allows for the maximum protection of our users.

Deciding which is the right fit of hand protection solution for you, can become complex - talk to our lab team to learn more about the test methods and standards that we are compliant with.